DT108 temperature sensors qualified for nuclear power plants

Discover the DT108 sensor range

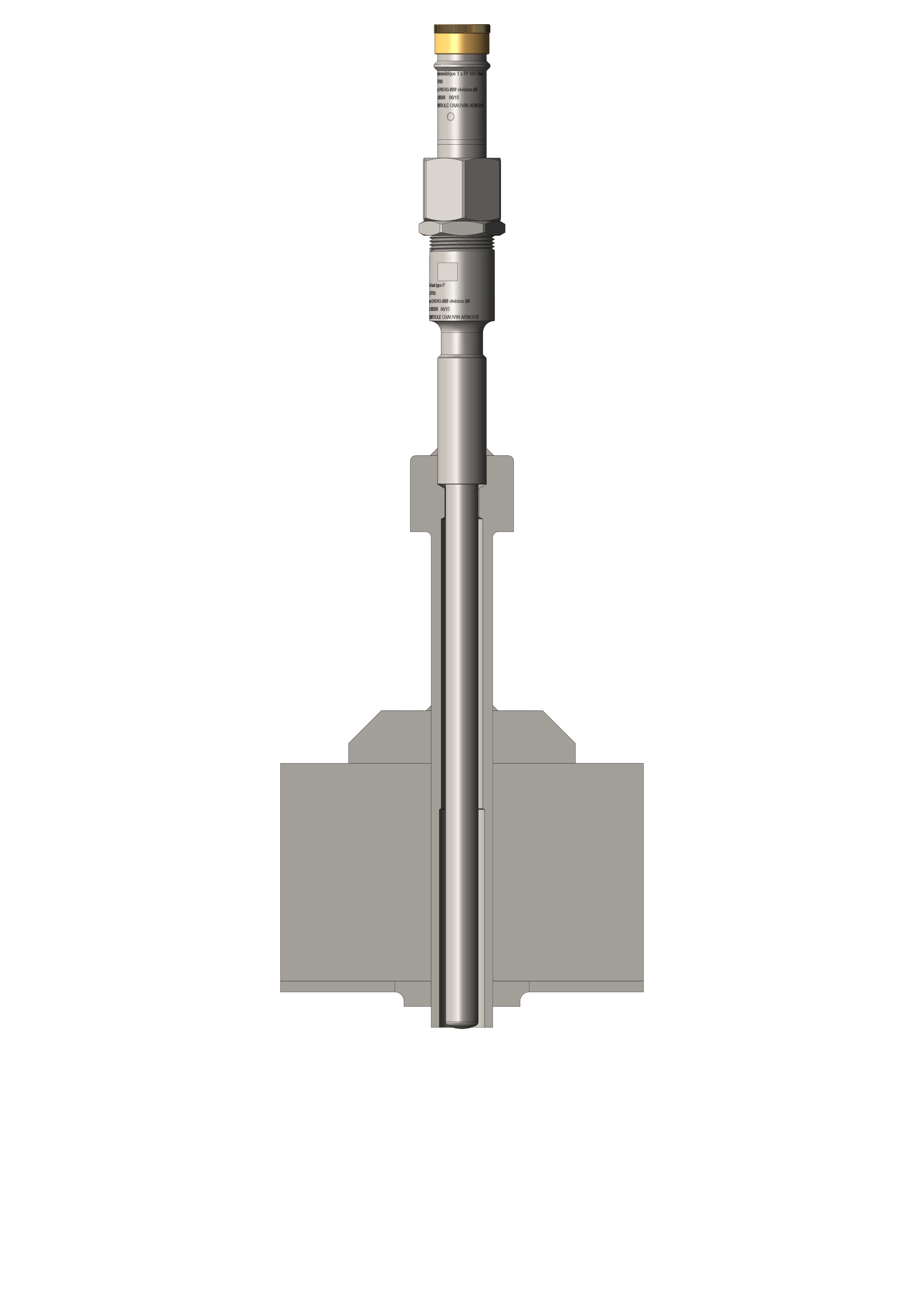

DT108-P

K1 and K2-qualified as per RCC-E, the DT108-P temperature sensor is specially designed to monitor the temperatures of the liquid and gaseous phases in the pressurizer. Mounted in a thermowell, it provides precise temperature measurements by immersion, even in post-accident conditions.

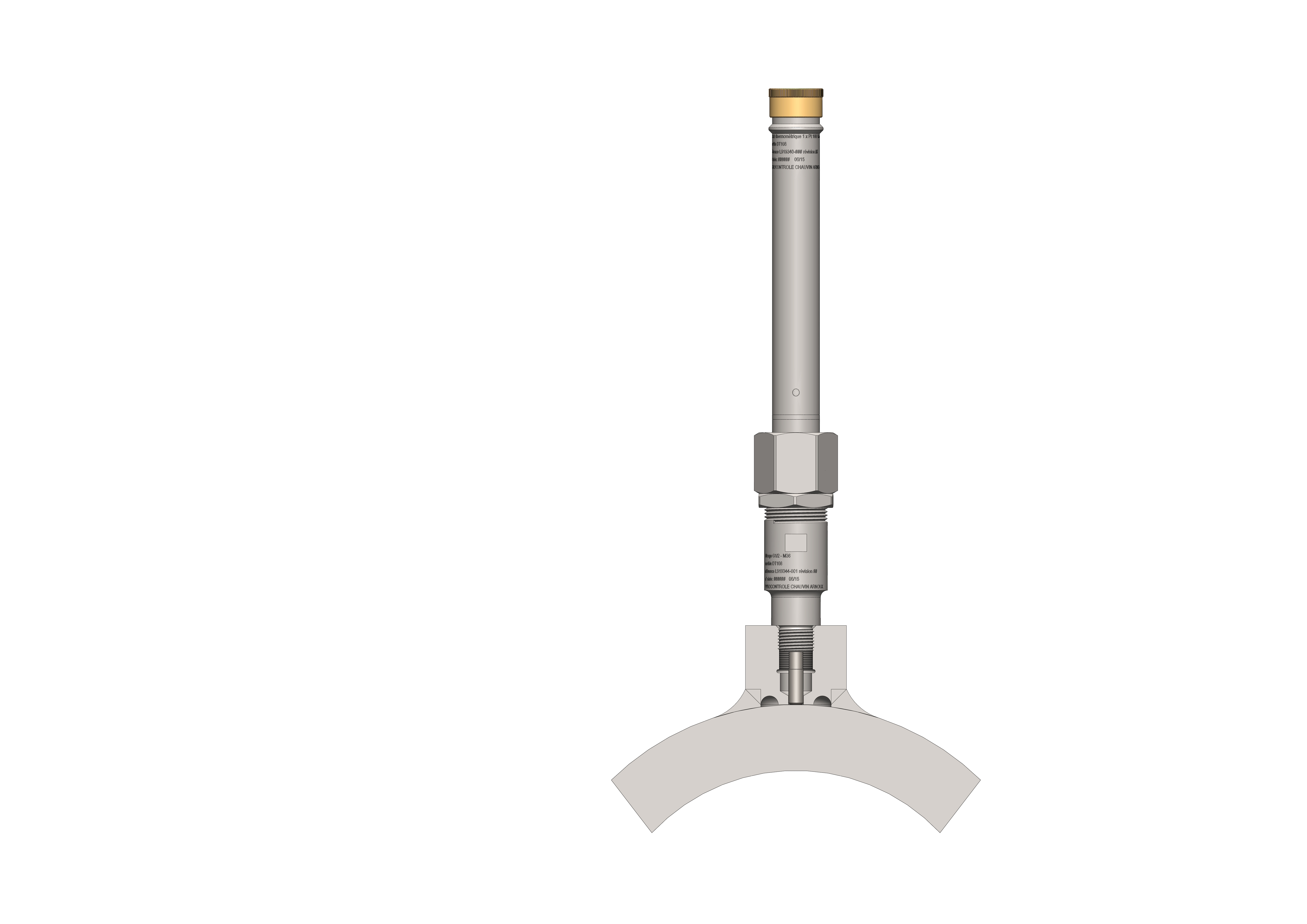

DT108-M1

K1 and K2-qualified as per RCC-E, the DT108-M1 temperature sensor can be used for precise monitoring of the temperatures of the fluids circulating inside the pipes, even in post-accident conditions. Screwed and welded on a boss, this Pt100 sensor provides reliable surface-temperature measurements. Another variant is available with a tapered thermowell: the DT108-DDG.

See details below.

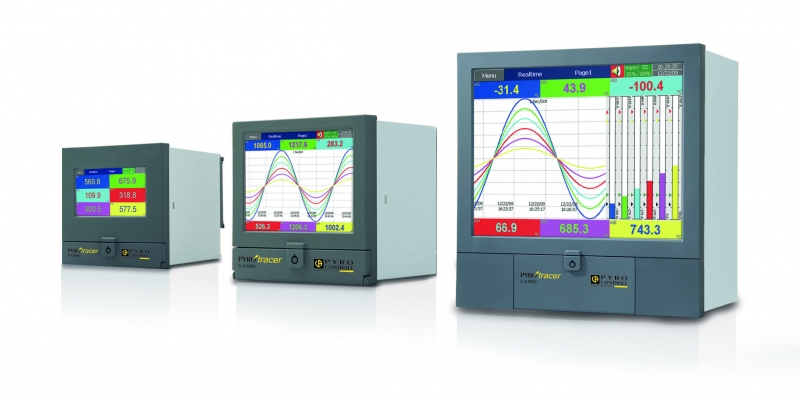

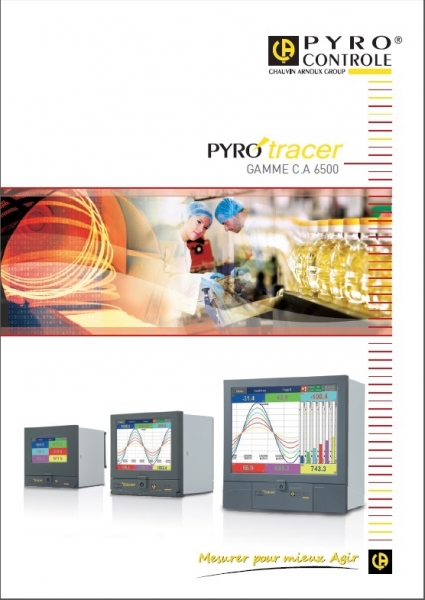

New C.A 6500 paperless data recorders!

Pyrocontrole is strengthening its offering of video recorders with its new-generation PYROtracer C.A 6500 with touch screens.

This new range of three paperless recorders (C.A 6510, C.A 6520, C.A 6530) benefits from the very latest technological developments:

- Faster recording rate

- Improved data security

- Customized configuration

- Intuitive operation

- Multiple recording channels

- Access to the data on site and/or remotely

All these advantages help to optimize your results in the field!

Secure data logging on up to 144 channels

These three recorders, from the standard model standard to the most powerful, cover every requirement, whatever the budget.

Depending on the model, the recording capabilities may extend up to 144 channels with an acquisition interval of 100 ms per channel, ideal even for the most demanding applications.

Customizable graphic recorders

For fully-intuitive handling, these recorders are configurable and therefore adaptable to match each customer's industrial environment.

With the Panel STUDIO software, users can create their own applications. The screens customized in this way allow you to monitor all or part of the installation on the recorder.

Master communication

Configurable as simple stand-alone units for unique data acquisition applications, these C.A 6500 recorders can also be set up in Master communication mode for supervising an entire installation. This configuration enables users to take full advantage of the recorder's performance features (secure data storage, supervision on a touch screen, remote viewing of the data, etc.).

Compact design

Particularly compact with a depth of just 170 mm, the C.A 6500 models are easy to flush-mount in a cabinet.

Depending on the applications, a portable version with a handle is also available which is easy to carry around, both in workshops and on outdoor sites.

Advantages

Easy-to-read, intuitive interface

> LED touch screen which can be customized for optimum display and easy reading

Multiple possibilities

> 3 to144 recording channels

Secure & fast

> Secure data

> 100 ms acquisition interval per channel

> Multilingual: 19 languages

Open and communicating

> Ethernet as a standard feature

> Modbus master, web server

Advanced functions

> Pulse-counting input

> Math & Logic functions

> Batch management

> FDA 21 CFR part11

> Customizable screens

> Multilingual, 19 languages

Compact, rugged design

> IP65 and reduced depth of casing

PA31ER adapter

To make sure your Qualistar+ can operate continuously, avoid spent batteries

This enables self-powering of the Qualistar+ via the phase from 100 V to 1,000 V, AC or DC. It is connected directly to the voltage inputs and is:

- IP53

- IEC 61010 CAT III 1,000 V / CAT IV 600 V

Thermocouples for AMS 2750E

The Aerospace Material Specifications Rev. E (AMS 2750E) define a certain number of rules concerning the heat treatments applied to metals in the aerospace sector. As a pyrometric measurement specialist, Pyrocontrole offers a complete range of thermocouples compliant with this standard.

Discover the various applications of these sensors installed in industrial furnaces.

Providing reliable, accurate measurements, this range of thermocouples fulfils the four control functions required by the AMS 2750E standard for thermal treatment furnaces in classes 1 to 6.

AMS 2750E thermocouple applications

AMS 2750E thermocouples can be used for four applications

· Sensors for ensuring furnace temperature uniformity (TUS - Temperature Uniformity Survey),

· Sensors for testing the accuracy of the readings (SAT -System Accuracy Test)

· Sensors for process control and recording

· Sensors for monitoring the temperatures of the loads (sensors installed on the parts)

Customers must perform the SAT/TUS tests with temperature sensors which operate independently from the furnace instrumentation.

Calibration service

Equipped with its own COFRAC-accredited metrology laboratory, Pyrocontrole can supply COFRAC calibration certificates and reports.

Find out more about our calibration services.

Pyrocontrole wins a major contract with Total Refining & Chemicals

Success Story

Pyrocontrole has won a three-year framework contract with Total Refining & Chemicals for the supply of in-line temperature measurement assemblies and associated services.

This contract covers all Total's sites in Europe and concerns in-line temperature sensors, thermowells and the associated services.

During the term of the contract, Pyrocontrole will supply ATEX temperature sensors for both new projects and revamping operations, guaranteeing the delivery of specially-designed subassemblies to Total's maintenance teams.

For this part of the contract, Pyrocontrole's R&D teams overcame the challenge from their competitors by innovating. Pyrocontrole has developed unique, revolutionary technology for ATEX temperature sensors: the id50 modular system.

This system makes it possible both to create made-to-measure sensors tailored to handle the specific features of each application and, on existing sensors, to replace only the obsolete module(s) on the sensors while maintaining their ATEX certification, thus avoiding replacement of the entire sensor. This solution helps to optimize overall equipment costs and reduce maintenance spending for these instruments.

In terms of the roll-out, as Pyrocontrole benefits from an international presence, local teams will support each site in France and across Europe.

Alongside this local roll-out, a contract-specific website has been set up to keep Total staff informed at all times.

The services covered by this contract include engineering, technical assistance, co-ordination and the activities linked to supply of the equipment.

This contract illustrates the confidence of Total Refining & Chemicals in Pyrocontrole's know-how for engineering R&D and temperature measurement management. With this contract, the French company Pyrocontrole has entered a new phase in its transformation into an international brand, demonstrating its ability to handle large-scale calls for tender.

Focus on the S44: Pt100 probe with output via connector

Pt100 probe with connector

Available in several different versions, this resistance temperature probe with output via a standard male connector is designed for universal use.

Available in several different versions, this resistance temperature probe with output via a standard male connector is designed for universal use.

For a measurement range from -40 to 200°C - choose the S44-200

For a measurement range from -40 to 450°C - choose the S44-450

Focus on High-Pressure Thermocouple

High-pressure temperature sensor

Ideal range for:

Ideal range for:

- Polyethylene and Ethylene (LDPE) production units

- Chemicals and petrochemicals industry

- general high-pressure applications

ADVANTAGES

- Pressure range up to 5,000 bars

- Very short response time: less than one second

- Resistant to shocks and vibrations

- Compliant with ATEX/ IECEx

- Very compact: 3 mm diameter

Operation

Developed to measure temperatures in high-pressure environments, this range of temperature sensors provides reliable, accurate temperature measurements of the fluid, with a response time of less than one second.

Comprising a plunging part, this temperature sensor is mounted using a screwed fitting and fixed with a conical-tapered fitting to ensure exceptional tightness.

The Range

Complete range of temperature sensors for high-pressure environments:

• Pt100 or thermocouple

• tightness by means of cone or sphere

• fastening by fitting or flange

• connection via connector, cable or head

• available in ATEX safety "ia" "ib" and "d" versions

• maximum working pressure: 3,600 bars.

High-pressure thermocouple

For customized versions, please contact us

Pyrocontrole's Metrology Laboratory at your service!

Metrology: calibrating temperature measurement

Taking advantage of its comprehensive mastery of the entire thermal process chain, Pyrocontrole proposes a set of calibration solutions for temperature sensors and temperature measuring instruments in all industrial sectors.

Taking advantage of its comprehensive mastery of the entire thermal process chain, Pyrocontrole proposes a set of calibration solutions for temperature sensors and temperature measuring instruments in all industrial sectors.

COFRAC or non-COFRAC

Depending on your needs, two levels of metrology services are available for your measuring instruments:

COFRAC or non-COFRAC with links to the national reference standards.

Whether you require COFRAC-certified* calibration or calibration with a certificate, our specialists will advise you. Find out more

*COFRAC accreditation no. 2-1385 for temperature measurement

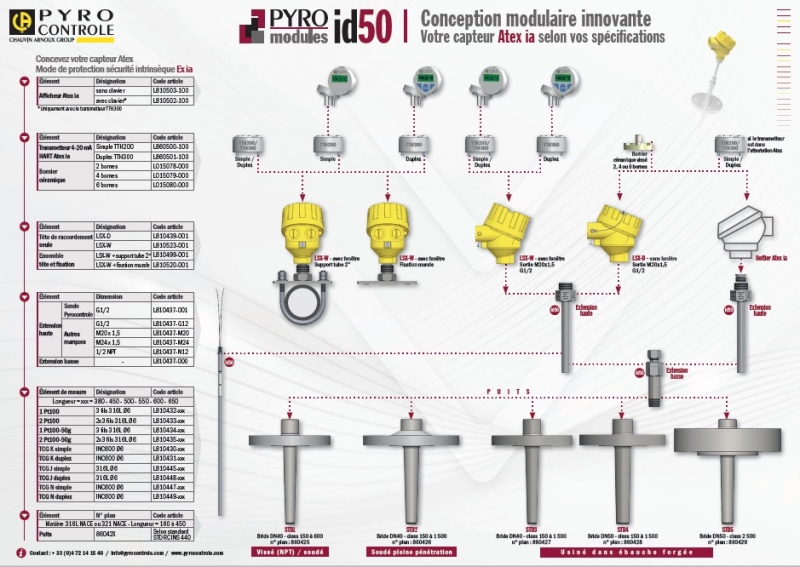

Innovation with PYROmodules id50

Developed for new installations and maintenance of Atex d/ia temperature sensors, the brand new PYROmodules id50 will change the way you work!

With PYROmodules id50, simplify your engineering work

& reduce your maintenance costs!

reduce your maintenance costs!

This innovative modular solution offers

two major advantages.

First of all, it allows you to design

tailored temperature sensors (RTD or thermocouples) to fit the specifications of your application. But it also fosters a different approach to maintenance work. Avoid high-cost solutions! With the innovative id50 system, you can use the id50 modules to replace only the faulty parts of your temperature probes.

id50 modules: a universal solution!

Another major advantage of this smart system is that the id50 modules can be installed on ALL makes of Atex temperature sensors while maintaining their Atex certification.

Discover our various modules and choose the guaranteed savings provided by the innovative Id50 solution!

To find out more: contact us!

-

Discover the family of id50 modules

Download the chart of the different PYROmodulesid50 modules

New 60 A TC CLIP

The TC CLIP range continues to grow...

Now available with a 60 A primary, the TC CLIP range of current transformers continues to grow.

Now available with a 60 A primary, the TC CLIP range of current transformers continues to grow.

- Split core

- Small size

- Built-in short-circuiting switch

- Reinforced hinge

See the brochure

See the brochure