Focus on signal processing

C.A 3420 signal converter

With its universal input, the brand new C.A 3420 transmitter from Pyrocontrole can be used to convert all your input signals into a stable, standardized output signal, even in difficult industrial environments. When used with the C.A 3401 programming panel, it offers an economical solution which is both efficient and user-friendly.

Universal solution

Mounted on a DIN rail, the C.A 3420 accepts a wide variety of inputs: RTD, TC, Ohm, potentiometer, mA and V. But the same universality applies to the choice of its power supply: AC (22...250Vac) or DC (19…300Vdc).

For the outputs, as well as a standardized signal (current or voltage), it is also equipped with two relays.

These two versatile relays can perform several tasks, including indicating sensor failures and high or low alarms. They are programmable and offer several triggering modes: on threshold, with latching, with time-delay, on rise or fall of the input.

Another important feature of this transmitter is that it is equipped with triple galvanic insulation between the input, the output and the power supply, thus ensuring optimum operating safety.

C.A 3401 programming panel

When used with the C.A 3420, the C.A 3401 programming panel is effective, user-friendly and packed full of functions:

- Easy programming: clipped onto the front of the instrument, it can be used to configure the C.A 3420 transmitter very simply without needing a manual or a PC, thanks to an intuitive drop-down menu. The interface texts are available in 7 languages: French, English, German, Spanish, Italian, Swedish and Danish.

- Copy: as it is removable, it can be used for quick duplication of configurations between one transmitter and another by simple transfer.

- Supervision: with its alphanumeric LCD screen, this panel allows you to check the real-time input and output values and the statuses of the process at a glance (relays and diagnosis of errors).

Safety

To ensure high security of the configuration and data, access to programming with the C.A 3401 can be password-protected. With its rugged design, the C.A 3420 is ideal for SIL* applications (level 2).

Complete and easy to learn, this global solution helps to reduce costs and optimize operational availability.

C.A 3420 technical details

Ask for a quotation

Check your cold chain!

COLD CHAIN UNDER CLOSE SURVEILLANCE

In the cold chain, particular attention is paid to temperature monitoring which is the key to health and safety. All the links in the chain must be monitored just as closely: cold stores, larders, freezers, preparation areas, etc.

Essential features of a reliable surveillance system:

- Continuous monitoring of the temperatures in cool areas

- Automatic recording of the values 24/7

- Secure data processing

- Monitoring of the utilities

- Alarms and alert systems

- Optimization of energy costs

> Discover the GLOBAL SUPERVISION OFFERING from PYROCONTROLE

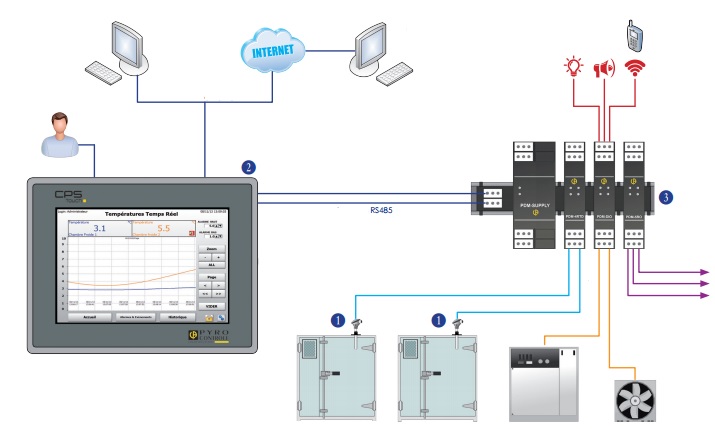

Components of the installation

1- Temperature sensors: Pyrocontrole Pt100 probes

2- CPS Touch® Human-Machine Interface: provides display, monitoring and recording of the data

Available in various sizes: 4.3", 7", 10", 15"

3-PDM input/output modules: interface between the installation and CPS Touch®

l PDM-SUPPLY: additional power supply

l PDM-4RTD: performs the temperature measurements

l PDM-DIO: monitoring of technical faults and indication of the alarms on relays

l PDM-5RO: energy management with standby modes

Wireless installation: to limit your wiring costs, it is possible to create "islands" of PDM modules as close as possible to the points of measurement. Communication with the CPS Touch® is then handled via the Modbus RTU protocol, via an RS485 link or, as an option, via a Radiofrequency wireless link.

If you need further information, please contact us

Sensor with in-situ calibration, an innovation from Pyrocontrole

Sensors with in-situ calibration enable you to monitor the changes in the drift of your temperature sensors over time by means of a method which is particularly simple to use. This patented technology offers significant advantages in terms of energy saving, productivity, quality and traceability.

IN-SITU CALIBRATION METHOD,

WITHOUT DISMANTLING THE SENSOR

This verification method by comparison is simple and quick to set up.

◗ Opening of the connecting head of the sensor to be checked

◗ Insertion of the reference standard sensor in the guide tube

◗ Connection of the reference standard sensor to the precision thermometer

◗ Temperature stabilization

◗ Calibration by comparison of the temperature on the reference standard and the temperature on the sensor to be checked

ADVANTAGES

Productivity gains:

with the in-situ method, you no longer need to shut down a furnace in order to calibrate its temperature sensors. Availability of the continuous production process is guaranteed.

Energy savings:

reducing the heating setpoint will help to extend the life span of your equipment and thus achieve energy savings.

Time savings:

implementation is simple and quick, requiring only a few minutes to calibrate a measuring point, which is a significant time saving.

Equipment replacement savings:

it is no longer necessary to dismantle the thermocouple to be checked, so there is no risk of breakage.

Safety gains:

the design of the new sensors includes total tightness inside the temperature measurement assembly, so there is no longer any risk of inflammable gas escaping when the connecting head is opened.

Flexibility gains:

all the calibration operations can be performed gradually throughout the year, without scheduling constraints, as it is no longer necessary to halt production.

>>Need additional information? Contact us

FOCUS on multipoint sensors

Multipoint temperature sensor

For precise multi-temperature mapping

Strengths

- High stability of the measurements

- Up to 54 measuring points

- Compliant with ATEX/IECEx

Operation

Fixed on the process by a flange, the multipoint sensor comprises several thermocouples of different lengths.

This multipoint assembly allows you to gather sufficient temperature-gradation information, in terms of quantity and quality, for quick mapping of the evolving phenomena on the installation. Various assemblies can be set up, depending on the application.

In the case of thermocouples mounted with a protective tube, a specific design has been developed to enable the tip of each thermocouple to be in contact with the tube, thus ensuring extremely accurate measurements.

See the product datasheet: Multipoint sensor

>>Need additional information? Contact us

Temperature sensor for cement manufacturing

Boost your productivity! Discover the Pyrocontrole temperature measurement solutions developed specifically for the cement industry

Temperature sensor for smoke box

Developed to measure the temperature in an extreme environment, this sensor withstands high temperatures and high concentrations of clinker dust.

The smoke-box temperature sensor offers a large number of technical advantages:

- Temperature withstand up to 1,300 °C

- Resists shocks and vibrations

- Sensor configurable to meet your requirements

Comprehensive offering

Resistant to dust, mechanical shocks and extreme temperatures, Pyrocontrole's temperature sensors go beyond the current standards in terms of rugged design and reliability.

Click here to see the whole range of sensors dedicated to this environment.

Chauvin Arnoux ESSENTIALS

Now is the time to discover the new Chauvin Arnoux promotion and choose the pack which matches your needs at special low prices!

SEE the Promo

Offer valid until 31st september 2017

FOCUS: S60-200 Pt100 sensor

Strengths

- Its cost

- Large choice of mounting options

Discover this standard sensor with its Pt100 sensor and output via connecting head. Equipped with an extension to reduce the temperature at the level of the head and mounted by a threaded connector, it measurement range extends from -40°C to +200°C .

Wide range of customizable models:

Wide range of customizable models:

- 2, 3 or 4-wire mounting

- Single(1) or Duplex(2) sensor

- Length and diameter of the stainless-steel tube

- Choice of connecting head:

shape, material: light alloy / stainless steel / plastic

with or without protective epoxy paint, IP 54 or IP65 , with or without built-in transmitter in the head

See the product page: S60-200 sensor

>>Need more information? Please contact us

Winter is coming: time to protect your installations!

PHR range: the solution for keeping your installations and process at the right temperature

Whether for your pipework, tank or container, etc., we offer a wide range of solutions to meet your needs: temperature control, frost protection, heating of solids or liquids.

We have a comprehensive range:

- Heating cables for surface temperatures up to 260°C / 450°C

- Self-controlled heater band

- Heater bands for surface temperatures up to 200°C

- Woven resistors for surface temperatures up to 200°C

- Heater blankets for working temperatures up to 450°C

- Heater sleeves for working temperatures up to 100/200/450 °C

- COMBINED floor and barrel heater for working temperatures up to 300°C

A specific requirement?

Contact us

We also develop tailored solutions,

so if you have any questions, please contact our experts