Choose your temperature controller!

4 steps to define the PID controller series matching your needs:

- Digital or Analogue?

- Control mode?

- Format?

- Type of application?

More than 200 references available in stock.

A product support technician is at your disposal to answer all your questions and propose the best product for your requirements.

Don't hesitate to contact him!

| Control mode |

Formats | Application | Input | Display | Series | |

| Digital | Self-adjusting PID |

24 x 48 mm 48 x 48 mm |

General |

1 programmable |

1 display |

STATOP Series 15 |

| Digital | Self-adjusting PID | 48 x 48 mm 48 x 96 mm 96 x 96 mm |

General |

1 programmable |

2 displays |

STATOP Series 30 |

| Digital | Self-adjusting, auto-adaptive PID |

24 x 48 mm 48 x 48 mm 48 x 96 mm 96 x 96 mm |

Process | 2 temperature and process inputs |

2 displays |

STATOP Series 60 |

| Analogue | On-off |

48 x 48 mm |

Simple |

1 defined |

None | STATOP 4841 STATOP 9601 STATOP 4 |

| Analogue | On-off | 96 x 96 mm 96 x 96 mm |

Simple |

1 defined |

1 display |

Pyrocontrole will be at the ADIPEC Trade Show

From 7th to 10th November 2017, Pyrocontrole will be taking part in the ADIPEC show (Abu Dhabi International Petroleum Exhibition and Conference) alongside the RACE (Rhône-Alpes Cutting Edge) collective.

We will be delighted to meet you in Abu Dhabi on our stand no. 9350 / Hall 9 in order to give you an overview of our latest developments in temperature measurement and control for oil and gas.

You can attend the event by registering on the ADIPEC website

Watch the video on the innovative PYROmodules id50!

With the id50 modules, you can create your temperature sensor to match your needs and, for your maintenance work, only replace the faulty part.

Another advantage of this smart system is that the id50 modules can be installed on ALL makes of ATEX temperature sensors.

Choose the innovative id50 modular solution!

Cement application!

From milling through preheating of the meal, heating and cooling of the clinker to storage, our measuring instruments can guarantee safety on your installations and the quality of your production, as well as helping to reduce maintenance costs and energy spending.

Resistant to dust, mechanical shocks and extreme temperatures, Pyrocontrole's temperature sensors go beyond the current standards in terms of rugged design and reliability.

Pyrocontrole temperature sensors:

a long-term solution at each stage in the manufacturing process!

»Check out our "Cement Application" web page

Focus on ATEX Pt100 temperature sensors

Pyrocontrole proposes a broad choice of customizable Pt100 temperature sensor models.

Pyrocontrole proposes a broad choice of customizable Pt100 temperature sensor models.

Discover our ATEX Pt100 (or Pt1000) temperature sensors in metal tubes and with output via connecting heads.

5333 programmable temperature transmitter

5333 transmitter from Pyrocontrole is very easy to configure and offers excellent accuracy. Reliable and flexible, it is ideal for a wide range of applications in the machine-tool industry and installation construction.

An ATEX version is also available.

Find out more.

Chauvin Arnoux ESSENTIALS

Now is the time to discover the new Chauvin Arnoux promotion and choose the pack which matches your needs at special low prices!

Offer valid until 31st July 2017

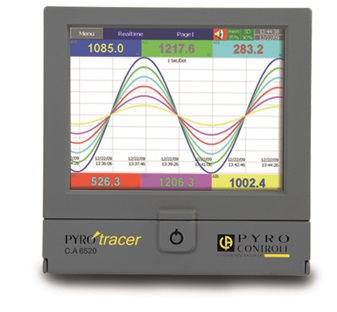

Focus on the Pyrotracer C.A 6520 datalogger

Paperless recorder on up to 72 channels

This touch-sensitive datalogger covers a wide range of applications.

Strengths

- Number of universal inputs: up to 24 channels and up to 72 channels with extension

- Compact size

- 5.6" touch display

- Extra-bright screen

- Sanctuarized data

- Sampling interval of 100 ms per channel

- PLUG & PLAY Input/Output modules

- 100 Hz pulse input

- Web server

- Modular

Accessibility of the data via the WEB with WEBSERVER

The data in the recorder can be viewed from anywhere in the world: all you need is a Web connection.

For this, the recorder must be connected to the Internet with an IP address supplied by the Internet service provider.

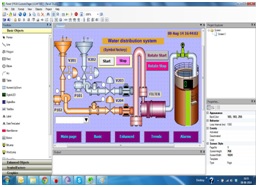

Customized screens

Customized screens

With the Panel PC Studio software, users can recreate their applications. This software enables users to have customized displays linked to their applications or process.

Configurable as a simple stand-alone unit for unique data acquisition applications, the C.A 6520 can be set to Master communication mode for supervision of an entire installation. With this configuration, you can thus take advantage of the recorder's performance features (secure data storage, supervision on touch screen, data viewable remotely, etc.).

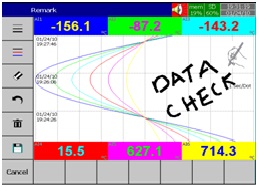

Writing messages on the curves

On-screen messages are particularly useful, as they allow you to highlight important events.

On-screen messages are particularly useful, as they allow you to highlight important events.

Operational in History mode.

Various display modes

Digital Views screen

Bargraph Views screen

Curve Views screen

Other important functions

Analog inputs: flexible sampling rate

Each analogue input can be set up with a specific sampling interval, such as 100 ms, 1,2,5,10,20,50 sec/Point and 1,2 Min/Point.

In this way, users enjoy significant flexibility for tracking their process.

Fast input

The digital inputs may either be DIs with standard High and Low logic levels or they may configured as frequency inputs (100 Hz).

System clock synchronization

The recorder's system clock can be synchronized via Ethernet and adapts automatically to summer/winter time changes

Increased security in password configuration

The password can be configured as normal or in CFR - 21 mode.

The increased security in normal mode uses a password.

FDA 21 CFR PART 11

Security in 21 CFR mode uses 9 password levels.

Batch management

With this function, the recorded data can be stored in batches. It will then be easy for the production and quality teams to process the data.

Focus on SURFACAL - Calibrate your surface sensors!

The main advantage of the SURFACAL method over previous methods is that you can calibrate surface sensors in conditions identical to their operating conditions.

SURFACAL is a BNE-LNE surface temperature reference for calibrating surface sensors in the laboratory or on site.

The main advantage of the SURFACAL method over previous methods is that you can calibrate surface sensors in conditions identical to their operating conditions.

# Calibration by comparison with the national references (LNE in France)

# Calibration of Pt100 surface sensors (2,3 or 4 wires) and thermocouples (as long as their specifications are metrologically compatible)

# Temperature displayed on front panel: +35°C to +300°C. Resolution: 0.1°C

# Accuracy: +/-0.6°C to +/-2.8°C

# Supplied with LNE Calibration Certificate at 2 points, 50°C and 300°C

# 316L stainless-steel surface as standard. Diameter: 90mm

# Aluminium surface available as an option

# Operation in horizontal or vertical position

# Transportable for use on site

Pyrocontrole wins a contract with the Chinese group CGNPC

Pyrocontrole has won a contract with the Chinese group CGNPC to equip reactors 3 and 4 of the nuclear plant at Fanchenggang with its DT034 sensors.

Pyrocontrole has won a contract with the Chinese group CGNPC to equip reactors 3 and 4 of the nuclear plant at Fanchenggang with its DT034 sensors.

Chosen for its unique performance features, the thermowell-mounted DT034 fast-response sensor won on its merits.

Installed on the primary loop circuit, the DT034 ensures accurate, instantaneous measurement with a response time under 3.7 seconds in normal operating conditions, even in the event of rapid variations. Qualified as K1, it combines technology and rugged design and is capable of withstanding the most extreme conditions in terms of earthquake, temperature and pressure.

In this context, Pyrocontrole will be supplying 60 DT034 sensors to equip reactors 3 and 4 of this native-type HPR1000 pressurized water power plant , Hualong One (1000 MW), for a launch scheduled for 2019 - 2020.

Already present on the Chinese nuclear market, Pyrocontrole is thus strengthening its position as a partner of choice acknowledged by the major groups.

An expert in temperature measurement for severe industries, Pyrocontrole has been developing qualified measurement solutions for the nuclear industry since the late 1970s, drawing on acknowledged know-how constantly enhanced with the latest technological advances. Partnering with both decision-makers and end-users, Pyrocontrole has developed a comprehensive offering of temperature sensors qualified as K1, K2, K3 and NC.

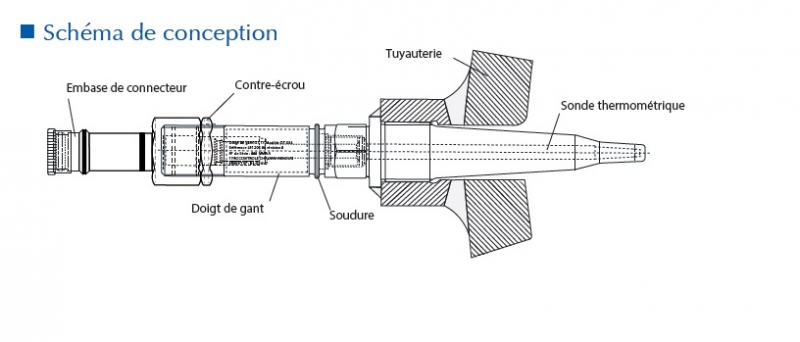

DT034 temperature sensor

• Mounted in a thermowell directly on the primary circuit and on the pump seals

• Fast response time (< 3.7 sec.

in normal operating conditions)

• Fitted on the N4 and EPR Series

• K1 qualification according to RCC-E

• Screened and consisting of a single piece

• Pt 100 element, 4 wires

• Temperature range: 0 / + 400 ° C

• Test pressure: 250 bars

Related products dedicated to the Nuclear Market

Check out the whole Pyrocontrole temperature measurement offering here