Industry market

The crucial concerns of the actors in industry are the safety of people and property, control of consumption and diagnostics or maintenance in order to avoid production interruptions.

The Chauvin Arnoux Group responds to these expectations by offering an extensive range of measurement, test and analysis instruments (Chauvin Arnoux/Metrix brands), comprehensive energy-cost control systems (Enerdis brand) and power controllers (Pyrocontrole brand).

Safety of people and property

For electricity, the applicable standards (NF C 15-100 in France, EN 61439 in Europe and IEC 61010 internationally) define mandatory tests and inspection for the safety of electrical equipment and installations.

Instruments such as installation testers, megohmmeters, network quality analysers and physical measurement instruments can be used to check earthing, electrical continuity or insulation quality in order to ensure safe operation. These are crucial parameters when delivering or renovating buildings, as well as in industrial production systems to prevent interruptions.

Other portable measuring instruments or energy solutions, such as multimeters, multimeter clamps, infrared cameras, temperature sensors or relays and loggers, can also be used to identify malfunctions and energy losses which may cause faults, fires or industrial production interruptions.

The Chauvin Arnoux Group proposes a comprehensive range of instruments and solutions to deal with the problems encountered by industrial companies, in accordance with the standards governing their activity and with the aim of supporting their production performance.

Watch our video

Reducing energy bills

Reducing energy consumption is another major concern for Industry. The ISO 50001standard (energy management) presents the inherent methodological guidelines and the recommended measurements on an installation, building or machine so that you can:

- Make a precise diagnosis,

- Analyse consumption at various points in an electrical installation.

For this purpose, the Chauvin Arnoux Group proposes a range of power and energy loggers (PEL100) and analysers (Qualistar ®+) which, when positioned correctly on the electrical network or cabinet, can be used to measure the exact consumption of each work station and thus draw up a load profile.

Enerdis's offering for energy metering on electrical switchboards also uses submeters (Ulys®), tariff meters, data collectors (ELOG®) and power monitors (Enerium®). These instruments are compatible with all the communication protocols (Ethernet, RS485, M-Bus, KNX) and provide direct readings of the measurements as well as a summary in a simple web browser.

E.online® is a complete energy performance solution which, via the web, directly processes data from several sources in industrial environments, whatever the type of energy involved (electricity, water, gas).

Preventive or corrective industrial maintenance

Each failure reduces the productivity of a factory and may damage the electrical installation. Industrial companies are well aware of this and seek solutions to identify any malfunctions on an installation and the locations of energy losses without halting production, whether for preventive or corrective maintenance.

The portable measuring instruments from the Chauvin Arnoux Group are designed for maintenance of networks and machines.

-The Scopix® digital oscilloscopes from Metrix ® monitor the machine commands and analyse the signals encountered.

-The range of voltage absence testers (VATs) is specially designed for testing machine motors.

-Thermographic (or infrared) cameras indicate the locations of energy losses or temperature variations and can be used to detect problems on electrical networks (voltage surges, overheating, etc.), as well as insulation faults, humidity in buildings, thermal bridges, etc.). Quick diagnostics can thus be performed to identify problems before it becomes necessary to shut down an electrical installation, which can be very costly. Thermographic cameras can be useful in many sectors of activity, including construction, the automotive industry, scientific applications, etc.

Thermographic cameras can be used to:

- Prevent hazards, and particularly fire

- Save energy and time

- Detect and solve problems before the first symptoms become visible

Because it saves time and money, infrared thermography is a reliable method for preventive or corrective maintenance on both the network and infrastructure.

In industrial temperature processes, the temperature controllers in the Thyritop® range from Pyrocontrole ensure switching of the high powers required by industrial thermal processes and help to protect production equipment over the long term. They can be used in a wide variety of sectors of activity and for multiple applications, including:

-Furnaces and process for the glass industries

-Chemical and petrochemical installations

-Injection and thermoforming presses

-Ovens, climatic chambers and autoclaves

-Industrial dryers.

In-situ calibration is another technology from Pyrocontrole which allows adjustment of temperature sensors without halting the manufacturing process.

To ensure accurate temperature measurements from its sensors, Pyrocontrole proposes a patented method for in-situ verification without dismantling the head of the sensor and without halting production. Simple, reliable and quick to set up, this unique technology for temperature sensor assemblies with in-situ calibration offers multiple advantages in terms of energy saving, productivity, quality and traceability.

Controlling electrical disturbances

In industry, the quality and variety of the machines connected to the electrical network may cause disturbances called harmonics which affect power quality and may damage the machines.

To quantify these "emissions", the electrical network analysers from the Chauvin Arnoux and Enerdis brands, used for power factor correction, are ideal instruments which ensure:

- Savings on the sizing of the electrical equipment

- Increased active power available on the secondary windings of the transformers

- Fewer voltage drops and line losses

- Lower electricity bills by preventing excessive consumption due to reactive power

The Group's Chauvin Arnoux, Metrix, Enerdis and Pyrocontrole brands offer this demanding market a broad selection of instruments for measuring, testing and supervising electrical networks which are now essential in the context of energy performance.

Industrial plant at Shanghai (China)

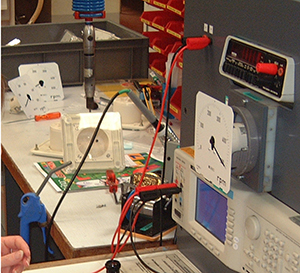

Shanghai Pujiang Enerdis joined the Chauvin Arnoux Group in 1998, as the company founded in 1995 was a joint venture between Pujiang Meter (famous in China for its panel meters) and Enerdis (France). 95 people now work in our 2250 Sqm facility in Shanghai.

We assemble a wide range of products from traditional analogue panel meters and transducers to the more sophisticated testers, DMMs and clamps. Our operations are ISO9001-approved and include functions such as R&D, Manufacturing, Quality Assurance and logistics, as well as local sales and marketing.

Our operations are ISO9001-approved and include functions such as R&D, Manufacturing, Quality Assurance and logistics, as well as local sales and marketing.

All our products are assembled according to the CA Group's high quality standards.

Industrial plant at Milan (Italy)

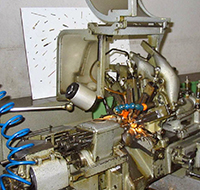

The history of our Italian subsidiary AMRA, the third to be set up after Poland (set up in 1936 and destroyed during the Second World War) and Germany (1965), began in 1975 with production of the OK Series relays.

In the beginning, two engineers formerly employed by CGS (later taken over by Siemens), which made these relays under licence, contacted Chauvin Arnoux to set up a subsidiary to continue manufacturing and selling these products.

They became the co-founders of our AMRA subsidiary.

The Italian subsidiary was founded on 4th February 1975 with the name AMRA (Appareils de Mesure de Relais et Automatismes). Legend has it that they initially began doing business from "a cellar" in the small Italian town of Monza. But the years which followed saw strong growth, boosting its revenues and enabling it to move to larger premises and expand its workforce.

In 1985, Mr. Salvatore Barbieri officially became the Managing Director of the subsidiary after the deaths of the other co-founders.

In 1996, AMRA bought out its main competitor on the Italian relays market, MTI..

2000: AMRA's expertise crossed the Atlantic after it signed a contract with a Brazilian partner for the manufacture of relays under licence.

2010 -2013: AMRA continued its ascension by obtaining ENEL certification and developing portable products particularly well suited to the Italian market: the "FTV" range of measuring instruments for solar panels.

Today, the subsidiary continues to grow under the leadership of Mr. Renzo Gnan, who was appointed in 2007.

In 2010, AMRA celebrated its 35th anniversary in the presence of all 45 of the subsidiary's employees.

A few figures:

Foundation: 1975

Workforce: 45 people

Location: Milan

2013 turnover: 10 million euros

Production: approximately 200,000 relays per year

Sales: AMRA relays, Enerdis relays, CHAUVIN ARNOUX measuring instruments (megohmmeters, network analysers, earth testers and current clamps).

Certification: ISO 9001 version 2000

Website: www.chauvin-arnoux.it

Industrial plant at Meyzieu (Rhône, France)

The Meyzieu site is on the outskirts of Lyon (France).

It is the manufacturing site for Pyrocontrole's temperature sensors and is organized in four major production workshops:

a large warehouse, a mechanical workshop for machining and welding and two assembly workshops, one of which is dedicated specifically to the nuclear sector

.

|

|

|

Each site benefits from ISO 9001 and ISO 14001 certification and is equipped with suitable equipment which is the focus of regular investment, but the Group is above all proud of its in-house expertise.

Industrial plant at Reux (Calvados, France)

Established in 1978, the site at Reux, near Pont-L’évêque in Normandy, currently employs nearly 120 people.

The 10,000 square metres of buildings are home to the Group's logistics: the warehouses for spare parts and finished products and the shipping department. More than 60,000 references are managed in these warehouses which store the parts needed to manufacture the measuring instruments assembled on the site and the finished products ready for shipping all over the world. The site is equipped with a single platform used to ship the instruments from the Group's brands for France, the subsidiaries and the international markets.

|

|

|

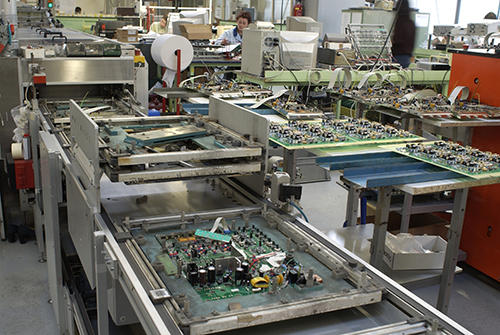

80 % of the products sold by the Chauvin Arnoux Group are assembled at one of the three French production sites. At Reux, the industrialization team handles development of equipment for testing new products and two workshops assemble, calibrate and check the products from the Chauvin Arnoux®, AEMC, Metrix® and Enerdis® brands.

Each site benefits from ISO 9001 and ISO 14001 certification and is equipped with suitable equipment which is the focus of regular investment, but the Group is above all proud of its in-house expertise.

Industrial plant at Villedieu-les-Poêles (Manche, France)

The site at Villedieu-les-Poêles opened in 1973.

It employs 115 people in an area of 4,000 square metres and specializes mainly in electronics. It manufactures flexible and rigid single- and doubled-sided printed circuit boards up to Class 5 and also handles the wiring of electronic boards. Up to 800,000 components are assembled there every week. In addition, Villedieu includes a workshop for assembling Chauvin Arnoux® and Metrix® finished products and Ampflex flexible clamps. The sites at Vire and Villedieu have their own warehouse for spare parts and raw materials.

.

|

|

|

Each site benefits from ISO 9001 and ISO 14001 certification and is equipped with suitable equipment which is the focus of regular investment, but the Group is above all proud of its in-house expertise.

Customer service

From a customer-focused culture to formalized implementation of the Quality policy

A top priority for the Chauvin Arnoux Group, customer satisfaction lies at the heart of our day-to-to-day concerns as it is both the reason for the company's existence and a prerequisite for its long-term survival. After more than 120 years in business, Chauvin Arnoux continues to demand quality in its product and service offering, quality in individual relations and quality in its dialogue with customers.

Quality of its offering and service

When the company was founded in 1893, quality was one of the requirements stipulated by the founders. The regulations and standards established throughout the 20th century and the current century are simply additional milestones in this process which the Chauvin Arnoux Group fully supports. Involvement of the personnel and an approach based on listening to customers are key elements for the success of our quality approach, which is now backed by the ISO standards.

INTERTEK CERTIFICATION

All the Chauvin Arnoux Group's sites thus have ISO 9001 IntertekTM certification (quality management) and guarantee control of all the processes contributing to customer satisfaction. Our sites also have ISO 14001 certification (environmental process).

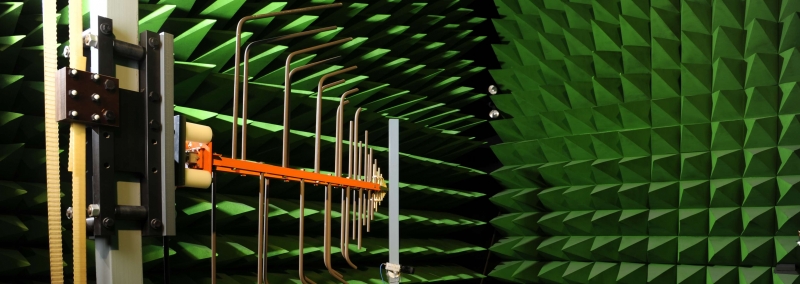

MANUMESURE: SERVICE BRAND

The Manumesure brand was created in 1973 to offer repair and calibration services for the company's measuring instruments as well as other brands. In this way, the Group's product offering (Chauvin Arnoux, Metrix, Enerdis, Pyrocontrole, AEMC and AMRA brands) is backed by After-Sales Service via the 12 technical centres français in France and the team of experts travelling nationally and internationally. Manumesure benefits from a large number of Cofrac accreditations for Calibration and Tests & Inspections, as well as an EMC compatibility test laboratory.

An EcoConception label has been established to formalize the company's commitment to recycling and recovery of raw materials so that our impact on the environment can be minimized.

QUALITY OF THE CUSTOMER RELATIONSHIP

Listening to what customers have to say, which is one of the keys for customer loyalty, is an integral part of the Chauvin Arnoux Group's corporate culture. For Chauvin Arnoux, listening to customers and the changes in their needs and markets is a crucial factor for remaining competitive.

The Chauvin Arnoux Group's sales activities have been organized to ensure a nationwide presence close to the customer. The whole of France is covered by assigning our sales engineers to geographical areas. Internationally, the team of travelling experts, the Group's ten subsidiaries and the networks of partner distributors provide full coverage in terms of prescription and professional advice across all the continents.

In this context, Chauvin Arnoux, like the Group's other brands Enerdis, Manumesure and Pyrocontrole, is an accredited training organization. They organize training courses in electrical measurement, testing and energy performance. Assistance in implementing measuring instruments and equipment and auditing of installations in industrial environments are also proposed.

In this context, Chauvin Arnoux, like the Group's other brands Enerdis, Manumesure and Pyrocontrole, is an accredited training organization. They organize training courses in electrical measurement, testing and energy performance. Assistance in implementing measuring instruments and equipment and auditing of installations in industrial environments are also proposed.

Eco-design

The CHAUVIN ARNOUX Group is committed to environmental responsibility!

Reconciling respect for the environment and the imperatives of industrial productivity has been at the heart of the debates since the 1992 Earth Conference in Rio and the emergence of the concept of Sustainable Development*, based on establishing a balance between environmental, economic and social conditions in future societies. Few countries or companies have taken this approach any further than the constraints imposed by the regulations, however.  CHAUVIN ARNOUX, a major international industrial company proud of its 120 years of growth and its family values, is nevertheless one of the precursor in this field. Helping to offer future generations the economic and environmental context which they have the right to expect matches the company's founding ethos.

CHAUVIN ARNOUX, a major international industrial company proud of its 120 years of growth and its family values, is nevertheless one of the precursor in this field. Helping to offer future generations the economic and environmental context which they have the right to expect matches the company's founding ethos.

The CHAUVIN ARNOUX Group has thus set up a voluntary Eco-design approach (called Eco Conception in French) which complies with the ISO 14000 environmental standard. The aim is clear: to reduce the environmental impact of the Group's products.

The CHAUVIN ARNOUX Group has thus set up a voluntary Eco-design approach (called Eco Conception in French) which complies with the ISO 14000 environmental standard. The aim is clear: to reduce the environmental impact of the Group's products.

From the design phase in our R&D units in Paris and Annecy through to recycling after use, the life cycle of a CHAUVIN ARNOUX®, METRIX®, ENERDIS® or PYROCONTROLE® product has already been adapted by our engineers to comply with the requirements in terms of:

> choice of recyclable and recoverable materials

> reduction of consumption by the products

> printed circuit-board size reduction, thus reducing the amounts of raw materials needed.

This environmental commitment by the CHAUVIN ARNOUX Group is as important as the functional, metrological and safety features of the measuring instruments designed.

However, the need to maintain our products' quality and price levels remains one of our core concerns.

.

The approach is formalized within the company by an environmental file (compliance details, dismantling sheet, etc.) drafted by the Quality Department which accompanies each measuring instrument.  To highlight this Eco-design commitment among its customers and partner distributors, the CHAUVIN ARNOUX Group has developed an "Eco conception" logo which is placed on the product literature and communication tools for its measuring instruments.

To highlight this Eco-design commitment among its customers and partner distributors, the CHAUVIN ARNOUX Group has developed an "Eco conception" logo which is placed on the product literature and communication tools for its measuring instruments.

* As defined by AFNOR (French standardization organization) in 2012, a State is considered "sustainable" if "the components of the ecosystem and their functions are preserved for present and future generations". In this definition, the "components of the ecosystem" include plants and animals, as well as human beings and their physical environment. For human beings, the concept implies balance in the fulfilment of the essential requirements: economic, environmental, social and cultural living conditions within a society".

Innovation

Chauvin Arnoux: 120 years of Design and Creation

With nearly 11% of its revenues currently invested in Research and Development every year, the Chauvin Arnoux Group has always been proud of the priority given to in-house design and development of its electrical measuring instruments. An important part of the Group's strategy, R&D at Chauvin Arnoux is based on the two keywords "Engineer-Manufacturer" engraved on the marble plaque at the entrance to the company's headquarters in Paris.

In addition to their symbolic significance, these words evoke the expertise of the teams in the Group's six R&D departments who constantly monitor future technological trends:

In addition to their symbolic significance, these words evoke the expertise of the teams in the Group's six R&D departments who constantly monitor future technological trends:

- Paris (France),

- Antony (France),

- Annecy (France),

- Lyon (France),

- Dover (USA),

- Milan (Italy)

design and develop 80% of our measuring instruments.

More than 200 highly creative engineers work in Research and Development worldwide to design our future instruments and respond to users' needs. The Group's R&D expertise is spread across three countries: France, the USA and Italy.

The team in Milan works mainly on designing relays, particularly for the rail industry, the team in Dover (USA) specializes in loggers and measuring instruments designed to meet the specific requirements in America and the French teams design most of the Group's products commercialized in Europe under the Group's brands.

As soon as Chauvin Arnoux was set up in 1893, the two co-founders, René Arnoux and Raphaël Chauvin, decided to split the responsibilities, with Mr. Arnoux working to boost R&D while Mr. Chauvin handled series production of the measuring instruments. In the first decades of the 20th century, this led to innovative instruments such as the Universal Tester (1927), the Hand-crank Ohmmeter, the Photo-electric Exposure Meter, etc. The years that followed also saw the launch of major classics, such as the wattmeters, the portable testers (Monoc 1959), the temperature controllers and the cut-off relays. When the first transistors arrived, they were naturally integrated into the design of new measuring instruments.

Under the guidance of expert engineers and spurred on by technical developments, the company has filed more than 350 patents to date.

Chauvin Arnoux is the result of 120 years of technical discoveries, human passion, know-how passed from one generation to the next and adaptation to the changes in the markets and technologies.

An important part of the Group's strategy, R&D at Chauvin Arnoux is based on the two keywords "Engineer-Manufacturer" engraved on the marble plaque at the entrance to the company's headquarters in Paris.

MANUMESURE

Metrology, regulatory testing and industrial maintenance

Manumesure provides metrological verification, maintenance and management of test, inspection and measuring instrument fleets in its laboratories or on customers' sites.

The company also proposes regulatory testing covering environmental issues (atmopsheric pollutant emissions, noise, etc.), personal safety (inspection of electrical installations, etc.) and hazard prevention (thermography, etc.).

Manumesure has structured its service offering on three major market segments:

- Industry,

- Environment

- Health.

With 12 technical centres in France and a team of travelling experts, the company provides full national coverage, thus guaranteeing a quick response wherever customers need it. Our experts often also provide services abroad.

With 12 technical centres in France and a team of travelling experts, the company provides full national coverage, thus guaranteeing a quick response wherever customers need it. Our experts often also provide services abroad.

The services proposed are all performed in compliance with the standards and constraints for traceability to the national reference standards. All MANUMESURE's laboratories have COFRAC accreditation certifying the technical competence of our teams and guaranteeing their impartiality.

The company is certified ISO 9001 and 14001 and MASE, and is approved by the French Ministry of the Environment and Ecology.

Manumesure is also a certified training organization, offering training courses in multiple technical fields to meet customers' needs.