At the heart of our products – Implementation of Thyritop 600 at an automotive group

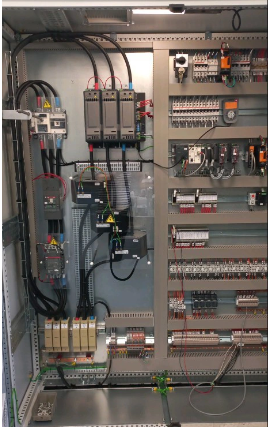

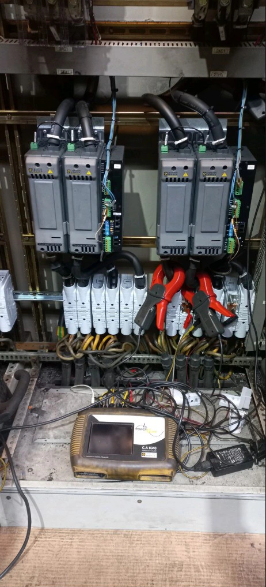

The temperature controllers from the Thyritop 600 series are installed in a gigantic oven. With a length of over 25 meters and spanning two floors, this oven is the beating heart of the automotive production site. Integrated into this industrial thermal process, our Thyritop controllers will optimize the operational and energy efficiency of the manufacturing ovens for blank parts, including those made of nodular cast iron and aluminum alloy (powertrain and chassis components). These parts will then be sent to the machining and/or assembly units and bodywork paint curing tunnels.

However, optimizing their installation requires manufacturer expertise and meticulous parameterization to meet the required quality standards. The challenge for Pyrocontrole and our partner lies in retrofitting this oven through an essential upgrade to achieve the ambitious goals set: producing up to 3.5 million crankcases per year. To accomplish this, the intervention of our experts is crucial. Their product knowledge and parameterization expertise are key to ensuring that production is efficient, safe, and responsible in terms of energy consumption.

.

The benefits of this collaboration are not limited to this installation. Indeed, its impacts are tangible on several levels. The controllers implemented will not only optimize the operational efficiency of the ovens but also enhance their energy performance. This represents a significant improvement in a context where sustainability has become an industrial imperative.

More technical information...

Products // Thyritop 600 3Ph and 2Ph power controller at 100A, 150A, 200A, and 400A

Voltage // 400V for 100A, 150A, and 200A, 690V for 400A

Loads // Star-connected resistances without neutral

Conduction mode // Wave train

Options // HB - partial and total load break detection + UIP - power control UxI, U², I², U, I

Fieldbus // Profinet

Did you know?

In industry, the term "retrofit" generally refers to the process of modernizing or upgrading existing equipment, systems, or facilities to make them more efficient, more effective, or compliant with new standards or requirements.

Retrofitting may involve various actions, such as installing newer components or technologies, upgrading software, improving energy efficiency, or even completely reconfiguring systems to meet new needs or goals.

This process is often used in sectors such as manufacturing, engineering, energy, aerospace, and others where existing equipment needs to be kept relevant and competitive in an ever-changing environment. Retrofitting can help businesses to extend the useful life of their existing investments while leveraging the latest technological advances, which may be more cost-effective than completely replacing equipment.